NAZCA-3D Features

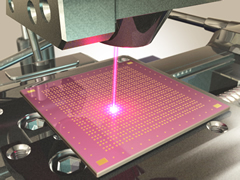

NAZCA-3D is a system designed to scan an object for measurement of its surface texture over a wide range at a high speed with a high degree of accuracy. Having a non-destructive laser displacement meter and a motor-driven two-axis stage mounted on specially designed jigs, the system is designed to scan an object in the XY direction for measurement to generate 3D data on its surface texture at a high speed. The system is also equipped with high-level image processing functions, such as 3D display and special measurement, to allow the 3D data thus generated to be processed and analyzed in various manners according to its intended use. The laser displacement meter and motor-driven stage built into the system are available in various types allowing you to select the best options for your system requirements.

Features

Various measurements are available by selecting laser displacement meters by precision or range.

Type 1

| 1. Measurement Accuracy | The system is designed with measurement repeatability of 0.2μm(*1).

This measurement repeatability of the system allows it to be most suitable for measurement of step heights ranging from 0.002mm to 0.6mm.(※1) |

|---|---|

| 2. Measurement Area (XY) | The system is designed to allow measurement with a scanning stage selected from the following types according to its intended use: 20mm, 50mm, 100mm, 200mm and 300m(*2). |

| 3. Measurement Range (Z) | The system is designed to allow measurement in the following range according to the type of the sensor unit used:

●0.6mm, 2.0mm when the sensor is of ultra high accuracy type (*3) ●2.0mm, 10.0mm when the sensor is of ultra high accuracy type (*3) |

| 4. Measurement Time | The system is designed to allow measurement of 1×1 mm in approximately 50 seconds (*4) and 10×10 mm in approximately five (5) minutes (*5). |

| 5. Customization | The system is designed to be customized for use with various types of stages such as a hot plate mounted stage for heating inspection, an inverted type stage for heavy object measurement, and a large-sized stage. |

*1.The data given as σ is obtained from the system's 20 repeated measurements of the specified stepped block's 0.0003mm step height using the ultra high accuracy sensor. (Measurement area: 5mm rectangle for each step)

*2.The system is designed to be customizable to allow use with a large sized stage for measurements over more than 300mm.

*3.The data is based on the system's bi-directional scanning of over 10,000 data points (100×100) at a pitch of 0.01mm.

*4.The data is based on the system's bi-directional scanning of over 40,000 data points (200×200) at a pitch of 0.05mm.

Type 2

| 1. Measurement Accuracy | The system is designed with measurement repeatability of 0.15 - 0.5μm

This measurement repeatability allows it to be most suitable for measurement of step height of maximum 180. |

|---|---|

| 2. Lens replacement | Select from 16, 25, 50, 50EXT, 75, 100, 125EXT, 150, 250 Selectable to use |

| 3. Measurement Range (Z) | ●High performance probe: 0.2mm, 0.6mm, 2.0mm

●Standard probe: 0.6mm, 1.8mm, 8.0mm, 18.0mm, 35.0mm, 45.0mm, 70mm, 180mm |

| 4. Measurement Angle | 170° |

| 5. Customization | The measuring range is designed to be customized by replacing the lens. |

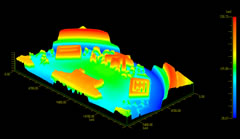

Non-contact & non-destructive scanning of an object for acquiring 3D data on its surface texture

Adopting a laser displacement meter for its measuring unit, the NAZCA-3D system is designed to acquire 3D data on the surface texture of an object by non-contact and non-destructive scanning of the object.

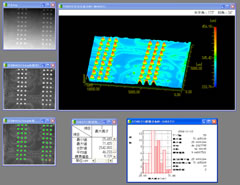

High-speed Real-time 3D surface data sampling

Through its built-in proprietary Mitani high-speed 3D data processing function, the NAZCA-3D system is capable of scanning 100×100 data for processing a 3D image in approximately 50 seconds*1. The system is also designed to allow even an object requiring scanning over a wide range *2 to be processed into 3D data in a short time period. The system's built-in RSV function enables the 3D data acquired by the scanning process to be graphically displayed on a real-time basis.

*1 This data is based on the system's scanning over a range of 1,000×1,000μm.

*2 The system's maximum measurement range varies according to the type of the stage used in the system.

Extensive array of image processing and analysis functions for 3D surface data processing

The NAZCA-3D system is designed to allow 3D data generated by the scanning process to be quantified in a flexible manner. Incorporating an extensive array of image processing and analysis functions such as multifunctional graphic 3D view and sophisticated 2D/3D correction, the NAZCA-3D system is designed to handle a wide variety of applications for 3D surface data measurement and analysis.